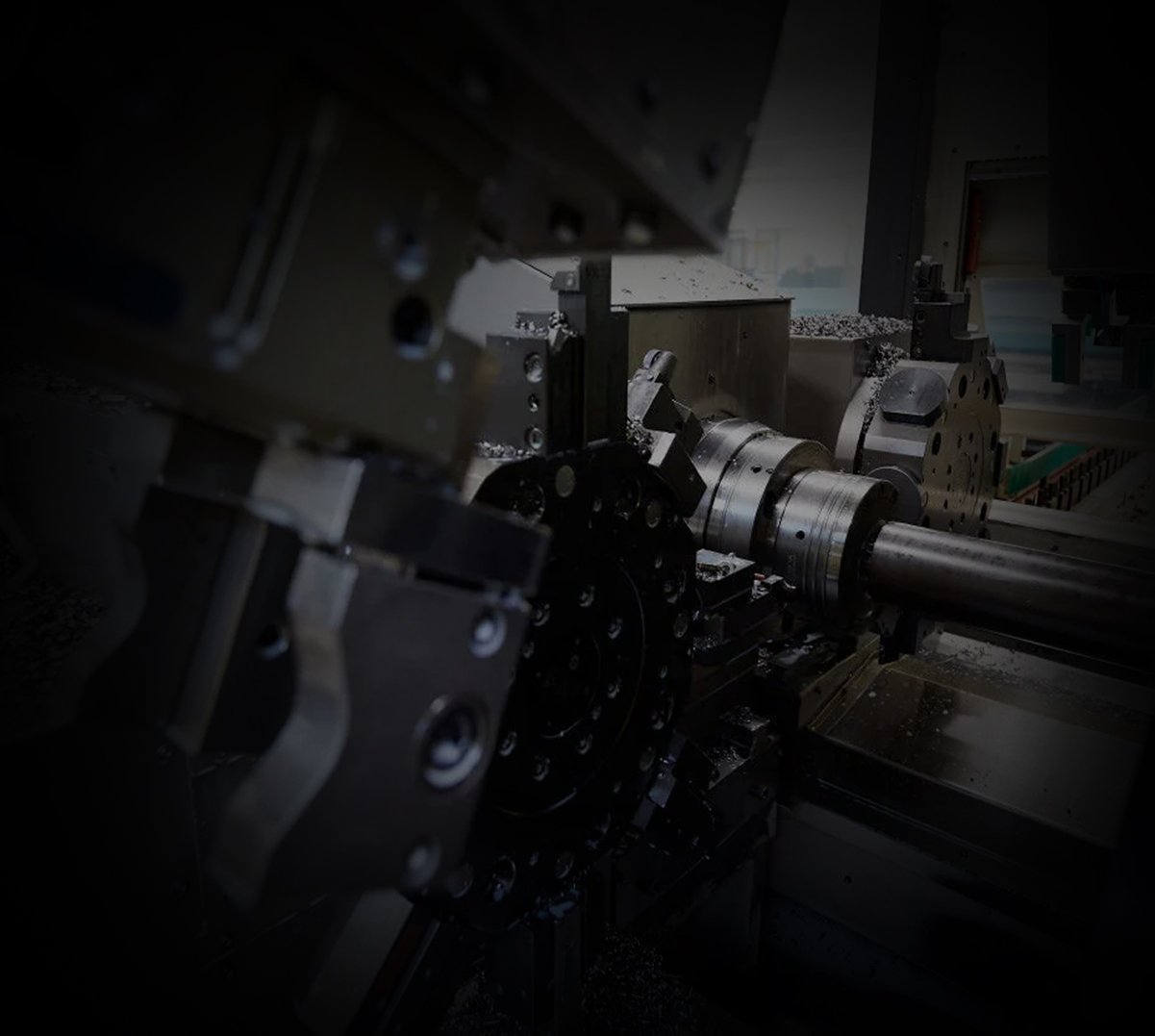

At our company headquarters in Balingen, we develop and produce with a vertical range of manufacture of almost 90% - and with materials and services predominantly from the region. 90 percent of our suppliers come from within a maximum radius of 250 kilometers. We also rely on regional partners for services. Production in low-wage countries? Not an issue for us.

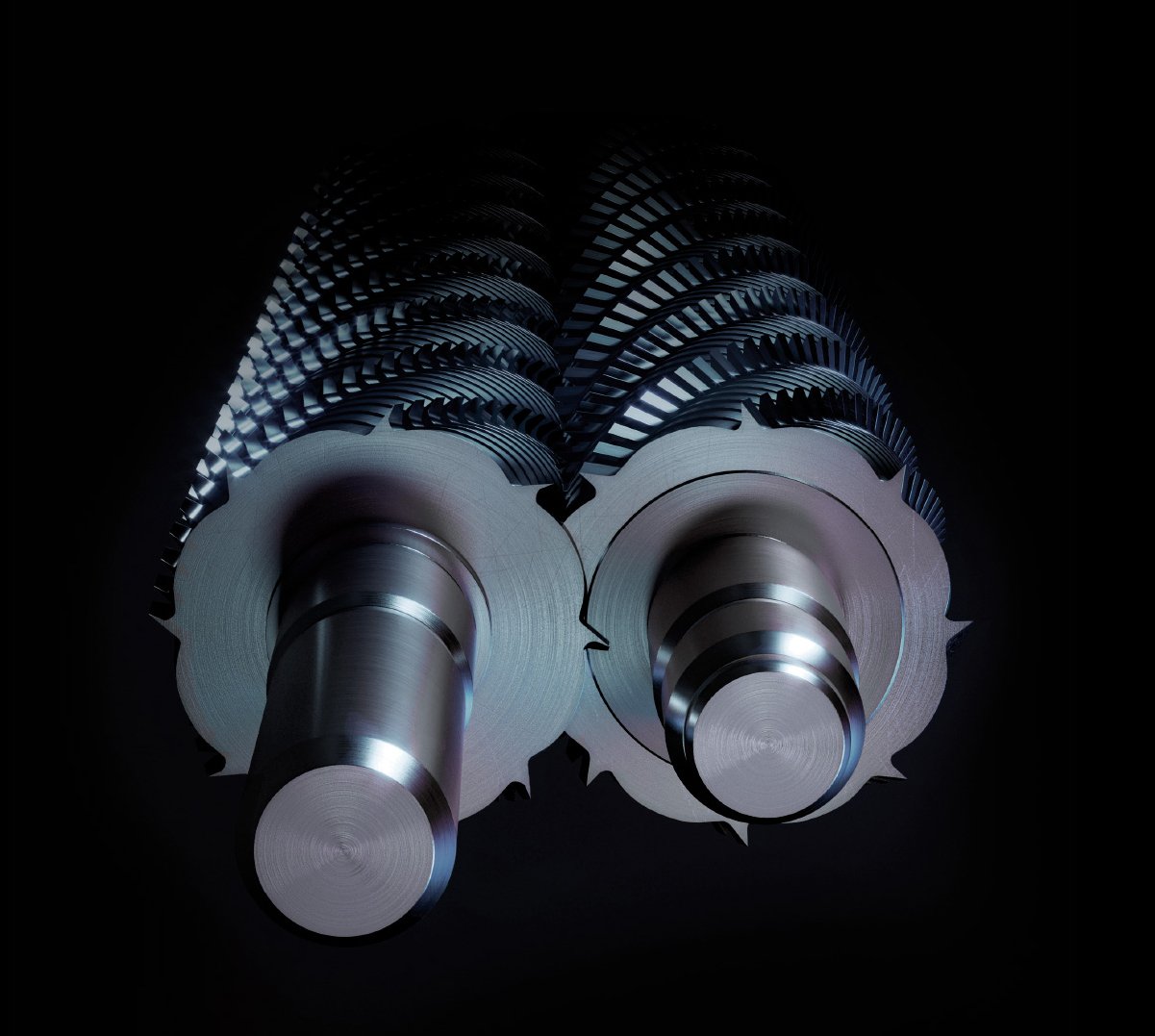

With us, you can be sure that only tried and tested raw materials are used: from the quality steel for our cutting units and cutting blades to the smallest screw. Details also make the difference in the application. You can't see our intelligent technology, but you can feel it: EBA products are particularly easy and convenient to use, giving you more time for the essentials every day.

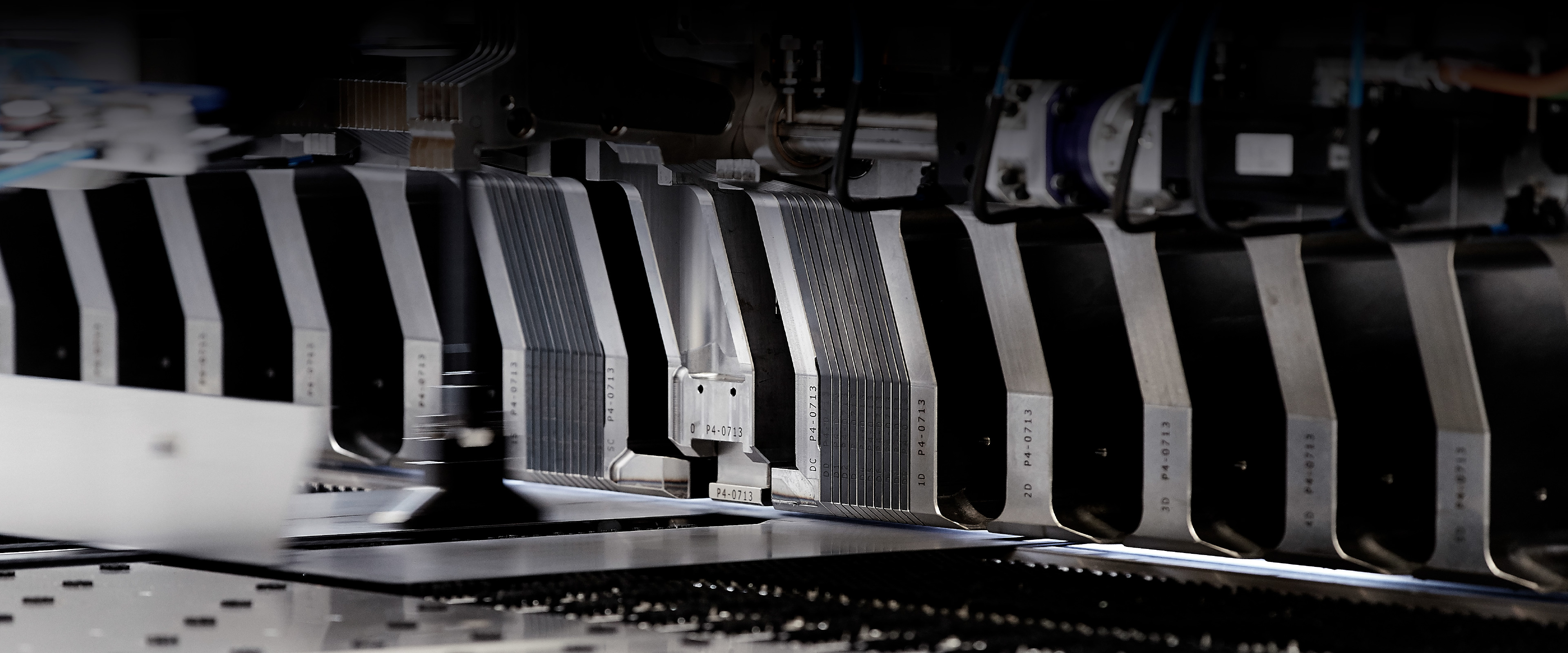

Fully integrated, environmentally friendly and, of course, state-of-the-art: our production is tailored to our needs. The Trumpf laser processing center for our sheet metal processing or the automated, state-of-the-art Salvagnini P4 bending center for our sheet metal assembly production are just two examples of this. However, we do not see technology as an end in itself: the focus is always on the best result. That's why even the most meticulous manual work still has its place with us.

Everything we do is a joint success. Our employees in the various departments make the right decisions together right from the start in order to offer you high-quality, extremely durable products. Your wishes and needs are also taken into account: We maintain long-standing relationships with our customers and business partners.

Generous with ideas. Frugal with resources.

Protecting the environment has been one of our values since the company was founded in 1951. We have been doing this consistently for just as long: for example, through high-quality materials and purchased parts from sustainable production, our powder coating center with a water-based washing system, the lead-free soldering system in circuit board production, clearly marked plastic parts for environmentally friendly recycling and optimized production processes that minimize waste and rejects.